Resources

Stop Being Repair Focused

November 14th 2022

Maintaining and repairing espresso equipment are not the same thing. Many service technicians only provide installation and repair services on an as-needed basis. In contrast, other technicians additionally provide detailed maintenance schedules alongside their sales of equipment to ensure peak performance and longevity of the equipment. How an equipment owner chooses to care for their espresso equipment will have a direct influence on the retailer and espresso service company they will want to partner with.

Espresso Repair Limits a Technician's Liability

Industry professionals should know that the service technician that just installed their espresso machine or repaired their leaking steam wand is not necessarily doing everything they should to prevent the equipment from deteriorating or breaking down. Espresso repair is not a licensed industry. Many technicians, stumble into the profession because they enjoy the troubleshooting aspect of espresso repair or there was a demand for a service technician in their community. For these technicians, meeting the urgent needs of the industry is their main objective, but it also means that the present job at hand, is all that they are focused on. Their responsibility ends once the installation has been completed or the mechanical issue has been resolved. Many technicians start out learning about espresso equipment on the job by accepting installation and repair assignments. As a technician becomes more knowledgable, they will gradually shift to equipment sales and a preventative maintenance model. Many, however remain focused on installation and repair only choosing to serve the spontaneous needs of equipment retailers. This unfortunately limits their responsibility to the equipment owner by placing maintenance accountability on the retailer that sold the equipment often unbeknownst to the retailer. Many industry professionals make the mistake of confusing espresso repair with preventative maintenance.

Preventative Maintenance is about Preventing Emergency Repair

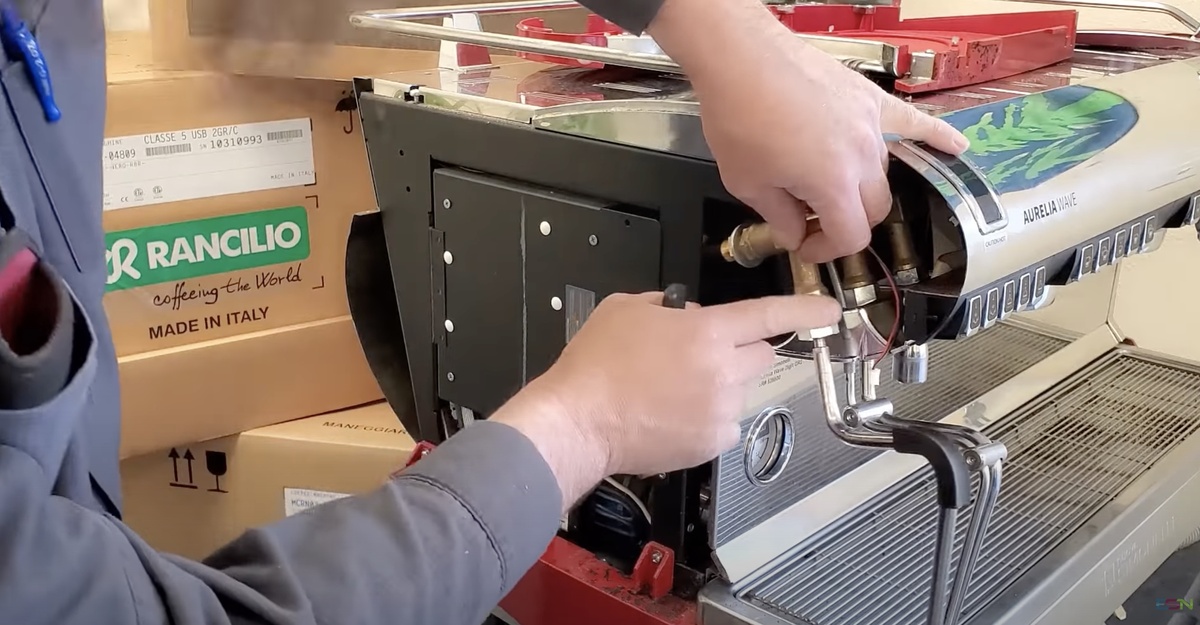

Technicians who provide preventative maintenance services are working to limit the amount of repair services a machine might need. For example, replacing  gaskets and lubricating components periodically to prevent a steam wand from leaking rather than showing up and repairing the leaking steam wand. Technicians who focus on equipment preventative maintenance provide a variety of unique services to identify issues and potential component failures.They also replace wear and tear items and specific parts that have a probability of failing or are not functioning correctly. Technicians will also check and adjust brewing temperatures and water for the protection of the machine and to ensure product quality. Preventative maintenance will, on average, take a service technician longer to accomplish than repair work which means an equipment owner should expect invoices to reflect higher amounts.

gaskets and lubricating components periodically to prevent a steam wand from leaking rather than showing up and repairing the leaking steam wand. Technicians who focus on equipment preventative maintenance provide a variety of unique services to identify issues and potential component failures.They also replace wear and tear items and specific parts that have a probability of failing or are not functioning correctly. Technicians will also check and adjust brewing temperatures and water for the protection of the machine and to ensure product quality. Preventative maintenance will, on average, take a service technician longer to accomplish than repair work which means an equipment owner should expect invoices to reflect higher amounts.

Preventative Maintenance is less expensive than unwanted downtime

The expense of maintaining equipment should be directly reflected in the quality of coffee the business serves. The additional cost of preventative maintenance services should also outweigh the cost of refurbishment or premature replacement of the espresso equipment and loss of business because of equipment malfunction or breakdown. Providing preventative maintenance service decreases unwanted downtime but it also requires a significant amount of additional effort for technicians beyond just working on or servicing equipment.

Technicians cannot accurately and efficiently provide maintenance services without thoroughly tracking the services they have provided and the parts they have previously replaced in the equipment. This documentation is accumulated for a technician(s) to review to know what has been done to a machine and when it was accomplished. Documentation is vital to prevent services from being overlooked or duplicated.

Service Documentation Educates Technicians

Service documentation is a professional courtesy and is also part of a technician’s continuous training. Whether just starting out or highly experienced, technicians gain valuable information about a manufacturer and their equipment models by collecting information. Understanding component longevity and why components fail are just a couple of examples. This and other knowledge strengthens a technician’s ability to prepare and provide faster services while increasing their value to the coffee industry. Choosing to maintain equipment does not mean the equipment owner needs to purchase a service contract but there are benefits to doing so.

Purchasing Parts in Advance Ensures Equipment is Serviced Promptly

Designing a service contract is laborious for technicians. Although manufacturers offer some guidelines for the first one or two years, these schedules often do not consider a business’s serving volume and other crucial factors. A technician must either design a service contract from their own personal experience with the machine, or from working with the same specific components and materials found in other equipment. They create a schedule for replacing specific parts and calculate the time they will need for labor and travel to execute services for a one or two-year service plan. Currently, many espresso machine parts are difficult to acquire and are on backorder. Purchasing a preventative maintenance agreement allows a service provider to purchase items beforehand that they will need to maintain the equipment over the described period. This will ensure that the equipment is maintained and serviced promptly. Retailers and equipment owners should never purchase a service contract that does not list specific parts to be replaced. Some service companies offer incentives with their preventative maintenance service agreements such as part discounts, after-hour service at no additional charge, or complimentary emergency repair services if something should happen between maintenances. Look to see if your service provider offers any of these services when you purchase your next espresso machine.

Creating a Service Schedule takes Experience and Education

For service technicians just starting out, writing a comprehensive preventative maintenance schedule can be challenging. Hiring a mentor with a high level of experience and education can help. If your service provider is not discussing preventative maintenance with you, it may be that they have made a conscious decision to only provide installation and repair services. Espresso repair can be highly competitive therefore, it is difficult for espresso repair technicians focused on on-demand service to design preventative maintenance schedules. Many service companies will try to do both, but most eventually land in one camp or the other.

Like many industry professionals, the Espresso Service Network is concerned about the quality of service available to equipment owners. As a retailer, if a service partner does not have a preventative maintenance program in place, we assist in helping them in either developing one or putting one in place on their behalf. If you have questions about the maintenance of your espresso equipment or have comments about this article, please forward them to solution_usa@esnservices.org. They will be warmly received.

Back to Articles